Finishing Processing / Assembling

Product Introduction

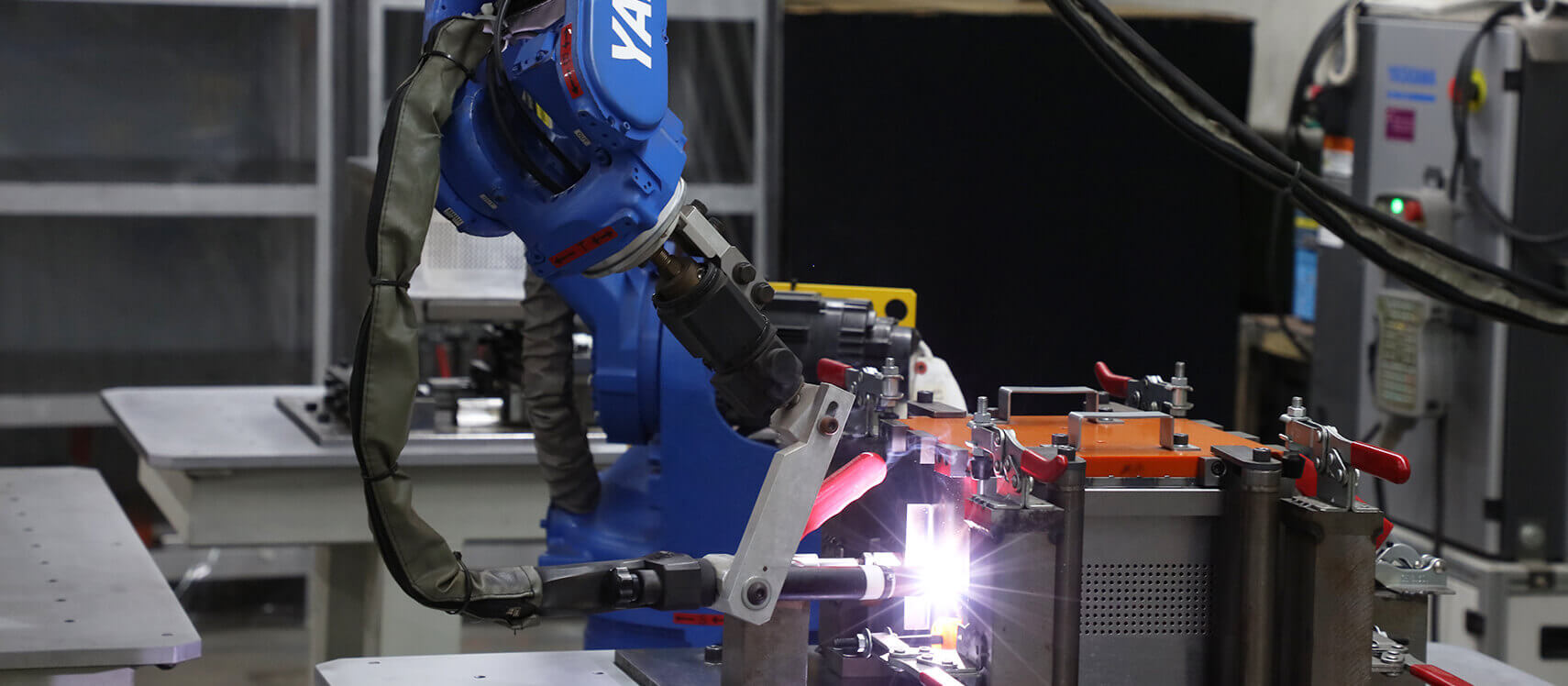

We offer various surface treatments like media blasting, chemical film, plating, and painting while adhering to the highest industry and environmental standards. Cheng Fwa can create the customized design pattern by laser engraving machine. Laser engraving can be used to create a grounding point for products with anodized surfaces. The automated welding system we use will improve welding quality and reliability, increase productivity, decrease the material cost, and reduce labor costs. We are also capable of silk screening, pad printing, laser etching, and label/decal printing to support different applications.

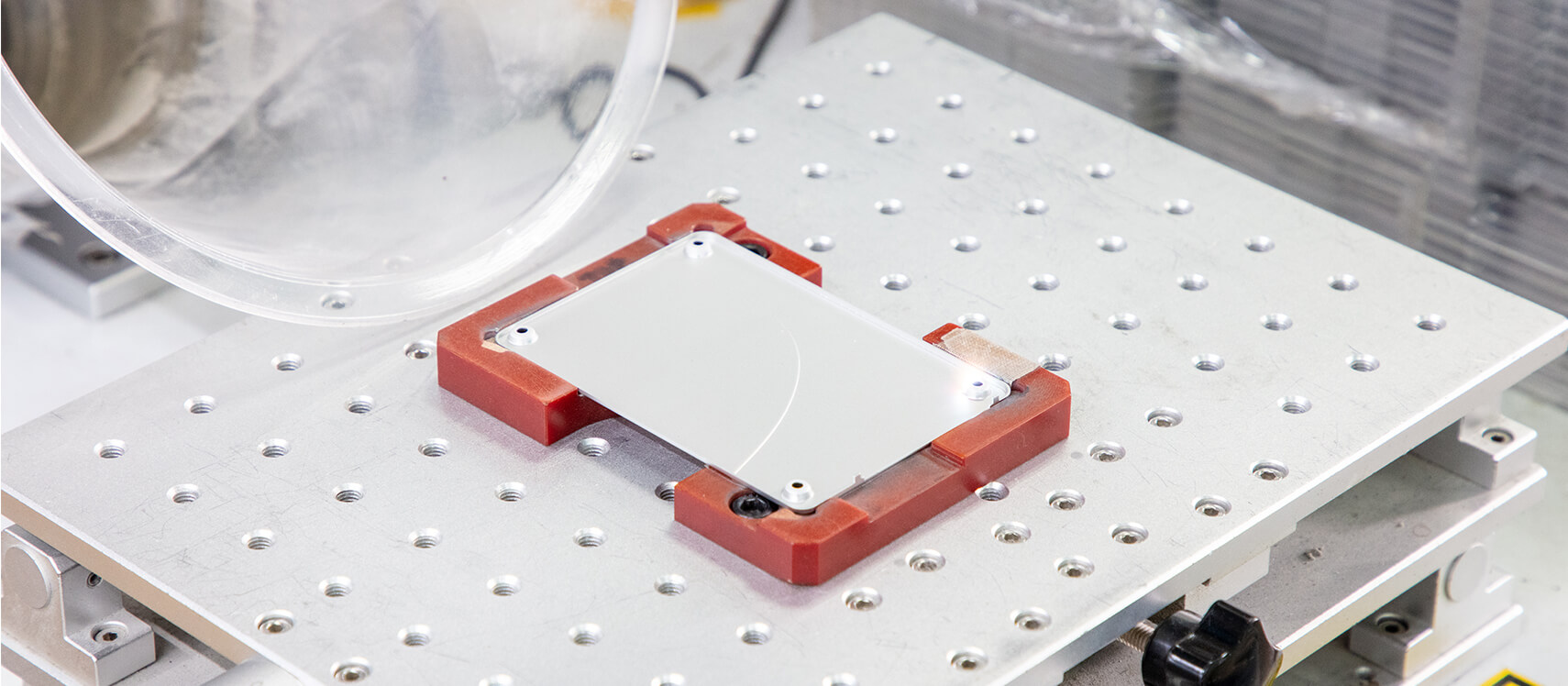

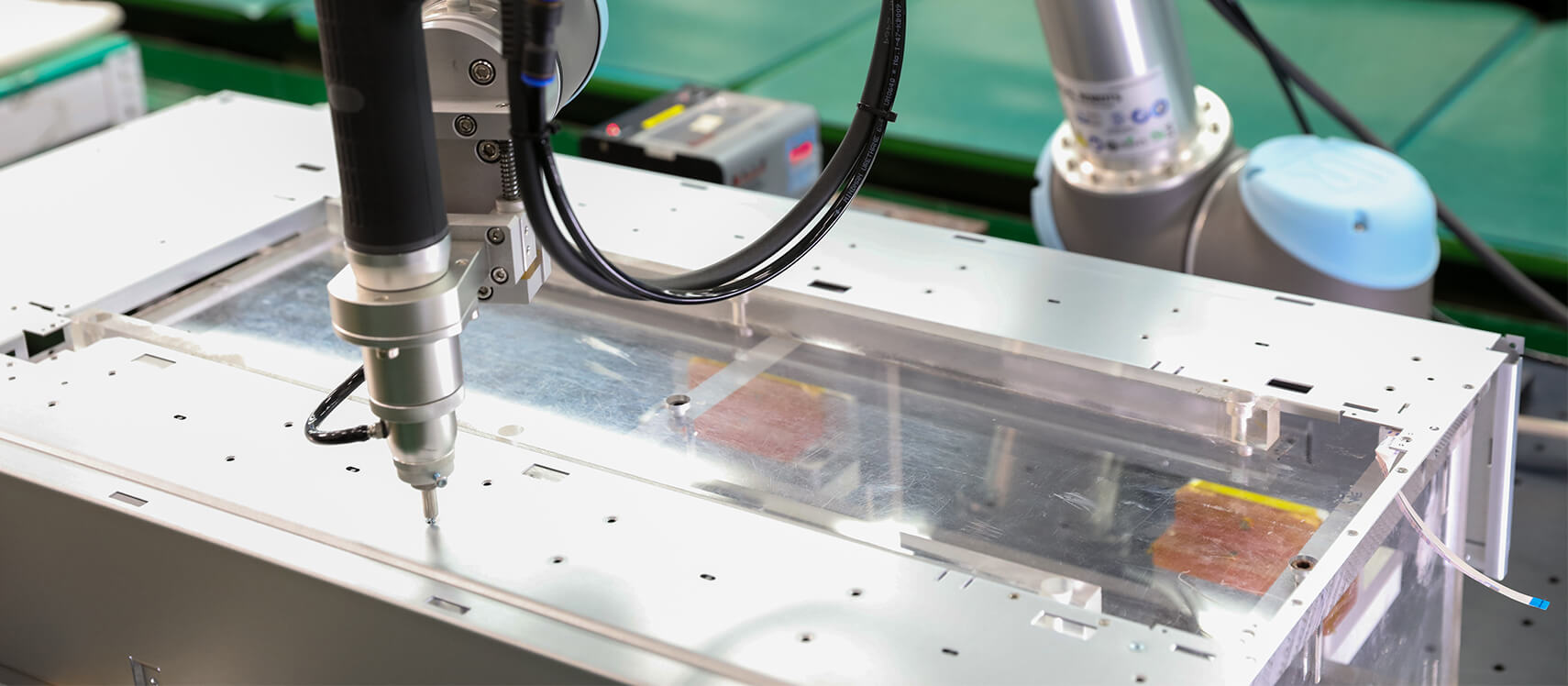

Our experience in the high-mix manufacturing world has fine-tuned our ability to handle complex assemblies with hundreds of individual components. Our team manages the supply chain to ensure all components arrive in time for production, and we perform inbound inspections to catch any material deviations upon receipt. Custom gages are used in each step of the assembly process to ensure everything is to specification.

To simplify the supply chain and ease environmental concerns, we offer value added kitting services. This allows your production line or customer to open one box and have everything they need to finish the job.

We also develop premium bulk packaging, which may be reused, to protect the product while in transit. To lessen the environmental impact, we are committed to working with you and your supply chain experts to determine what is needed to reduce, reuse, and recycle the packaging materials.