Plastic Injection

Product Introduction

We are well-equipped to handle all your plastic injection with our dedicated injection molding facility and expert tooling engineers. Keeping with our commitment to fast turnout during development, we can get quick tools up within 2 weeks. We can also convert into formal tooling within 6 weeks, complete with Mold Flow Analysis and access to premium resins.

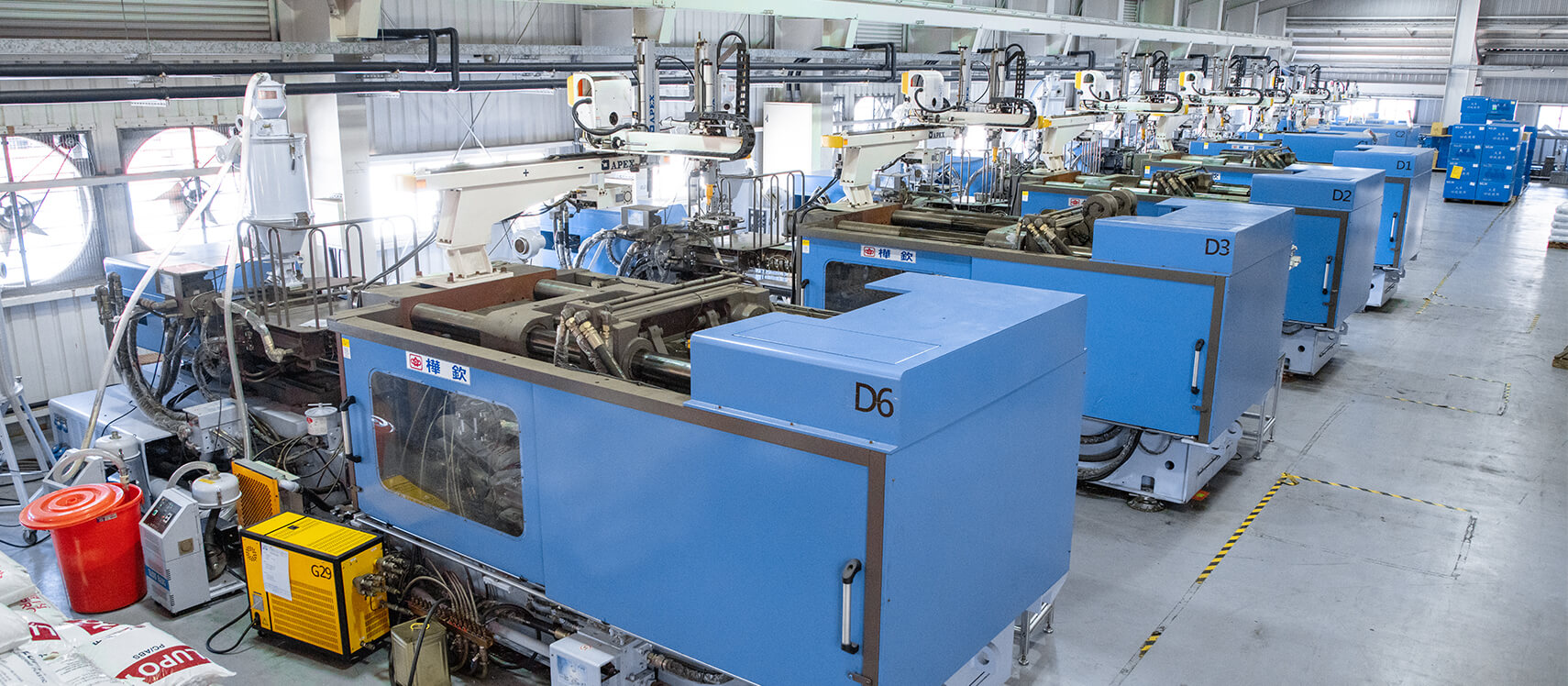

Capacity

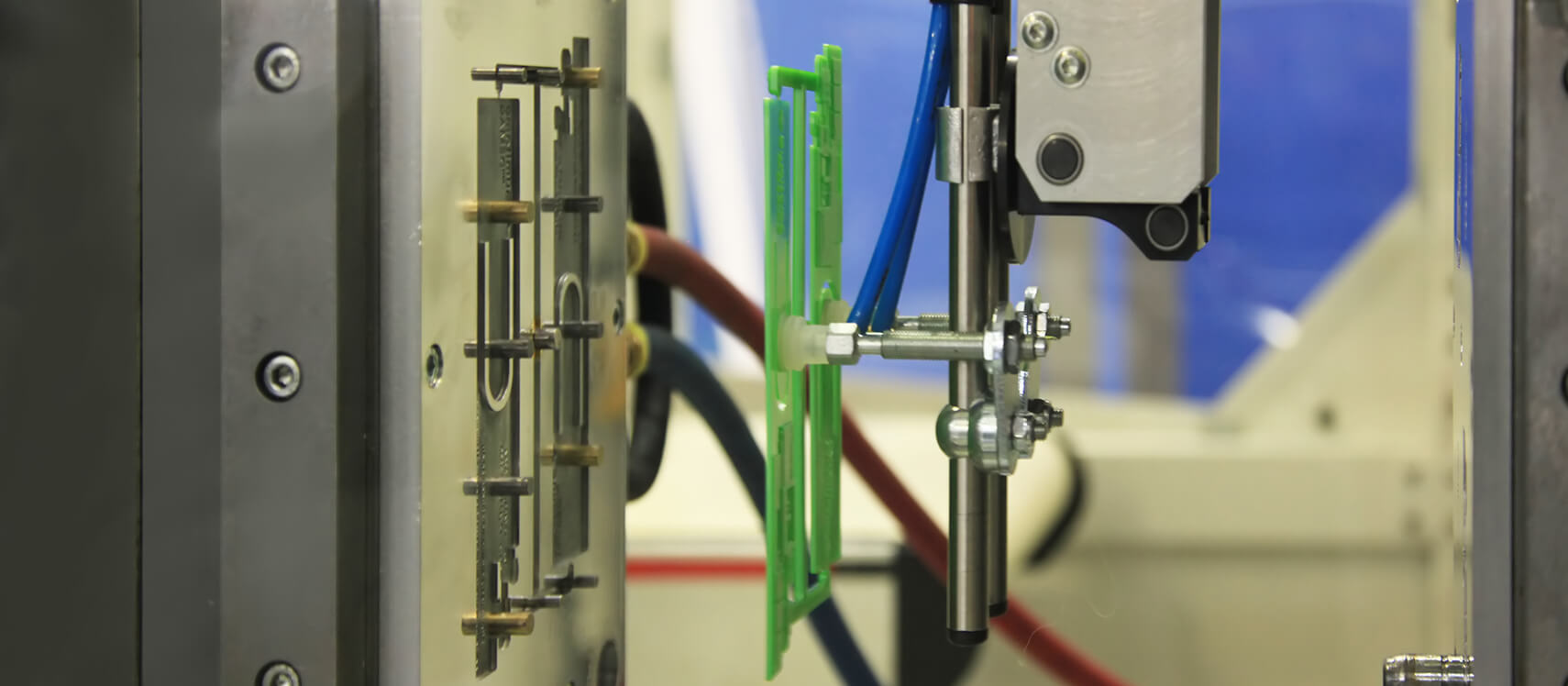

Our services include plastic injection, printing, heat staking, and assembly. Through the horizontal injection molding machine, the liquid plastic is poured into the plastic mold form the final products. We seamlessly adjust our production line to meet different product requirements, whether for low-volume to mass production.

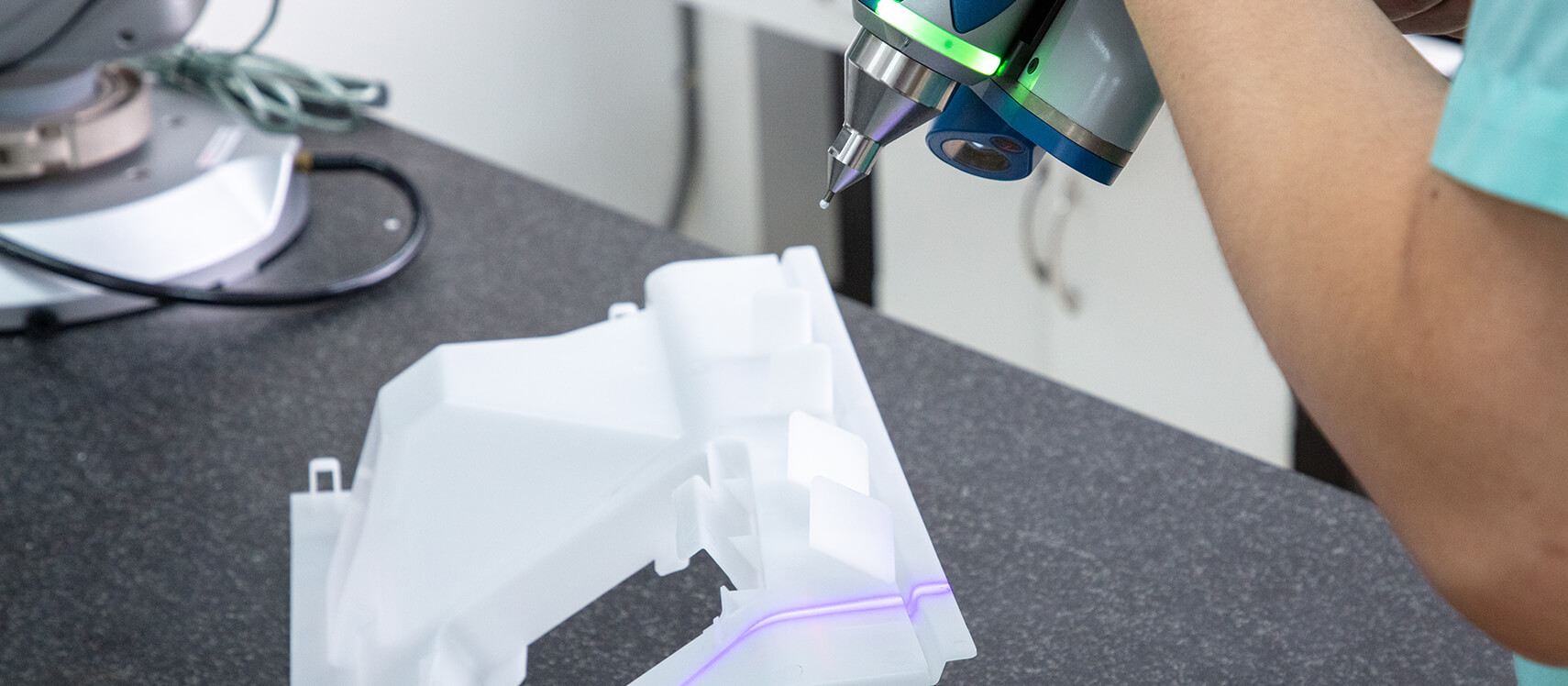

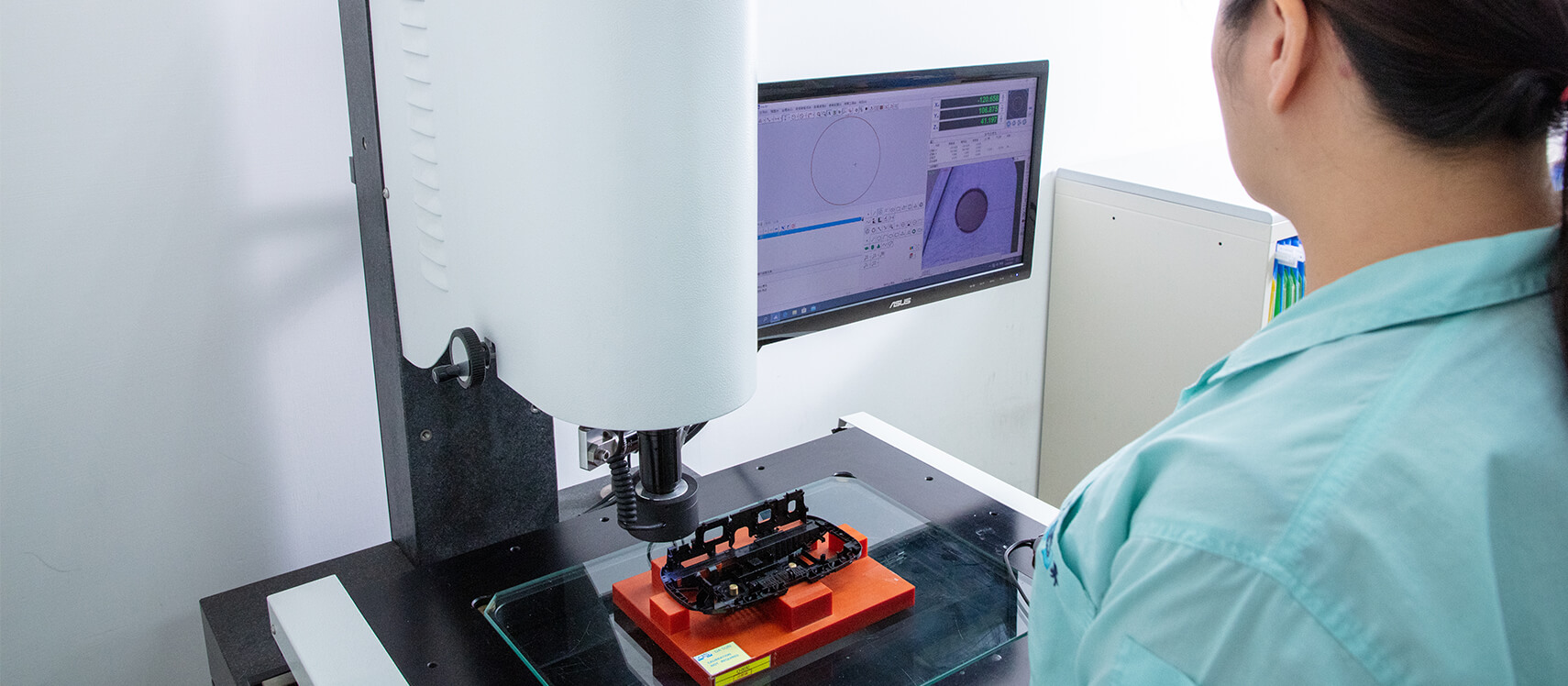

We have 35 sets of high-precision plastic injection machines in the plastic injection department. To ensure a consistent standard of quality, each machine is equipped with a robot arm and control system to decrease potential damages that can occur during manual operation. The finished products of plastic injection are inspected by the Edge Faro Arm robotic arm measuring system. A 2.5D image measuring instrument and falling ball impact testing machine also ensure product standards are met precisely and consistently.

Materials that can be processed are engineering plastics, such as PC, ABS, PMMA, nylon, plastic steel, etc. Our professional plastic injection team produce plastic parts and accessories, which can be applied to various industries including home appliances, medical treatment, digital communications, information storage equipment, and the industrial computer industry.

Plastic injection is a service we offer to strengthen our turnkey manufacturing solution. Quick tools can get the job done within 2 weeks and formal tools are completed within 6 weeks. With a completion of Mold Flow analysis, we can support all your plastic injection needs.